Daikin VRV 3-Pipe Heat Recovery system with a multi–Branch Selector Box for each apartment. The system was installed and commissioned 2 years ago.

Daikin VRV – Remote Service Case Study

The Resident of an apartment has opened an urgent service ticket advising the Living Room and Bedroom units were not heating properly. Also, sometimes it felt like they were cooling while calling for heat.

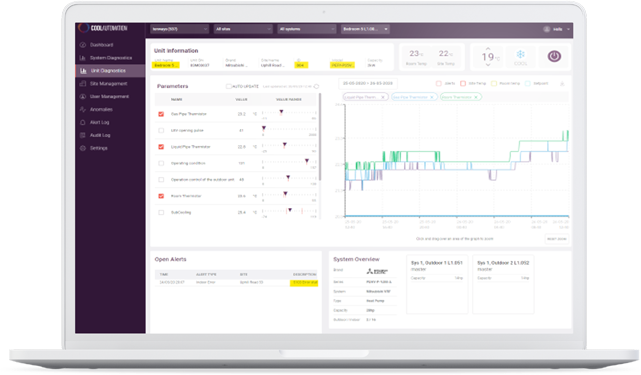

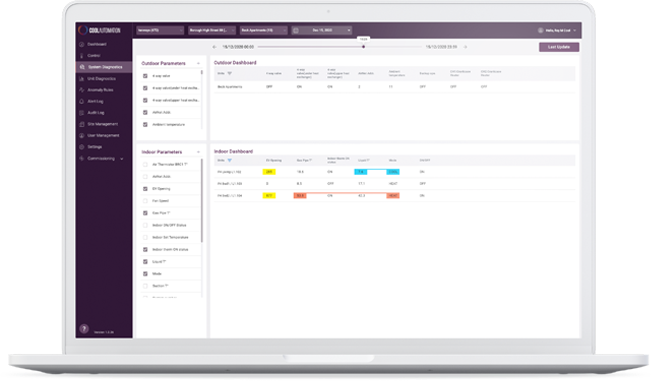

As the site was connected to the HVAC Remote Diagnostics solution, the HVAC engineer activated an anomaly test operation. Following several deep remote operation tests, the Service Solution suggested that it is likely that there is cross-communication wiring between different ports on the Branch Selector Box. As a result, while switching ON the Living Room indoor unit, the refrigerant was flowing to another indoor unit.

As an immediate temporary solution to allow the residents to have heat, the engineer suggested that the two crossed units should be operated simultaneously until the engineer visits on the next day.

An engineer then traveled to the site and corrected the fault.

Engineer time on site for fault correction: 45 minutes.

| Traditional HVAC Service | Remote HVAC Service |

|---|---|

On-site long data recording with the essential need for the error to re-emerge (will not appear if both units are operating) | Offsite remote system test and fault finding |

Multiple trips to the site are expected |

Less than 1 hour of On-Site Junior VRF Engineer |

Analysis of the raw data gathered with minimal assistance from the tool, involving a Senior VRF expert on-site for a considerable amount of time | Remote fix verification |

On-site fix | |

On-Site verification test |