The customer commissioned a Daikin VRV Heat Recovery System, and the HVAC worked for ~2 years. The customer was satisfied with the HVAC.

Faulty Daikin VRV Compressors Case Study

In a rare case, after ~2 years both of the inverter compressors were faulty.

The Customer decided to switch the service company for the replacement. The compressors were replaced and activated, but the root cause was still unknown.

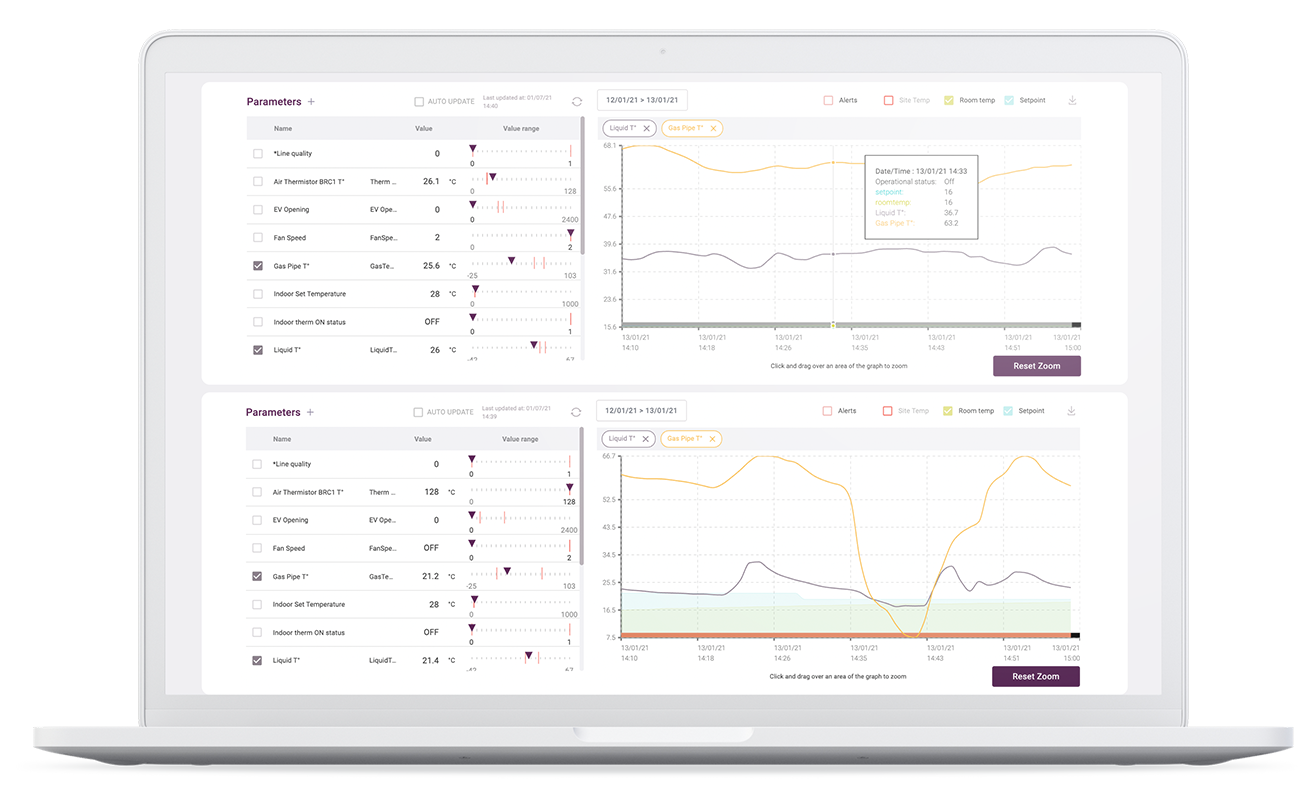

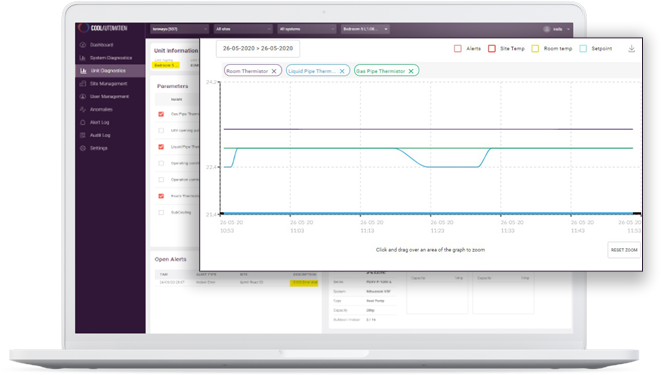

The service team performed a checkup, using CoolMasterNet and CoolAutomation’s HVAC Remote Diagnostics solution – and found irregular readings.

When both inverter compressors units were heating – both were heating just fine. But when one unit was in Heat mode and the other was Off – the unit in Heat mode was actually cooling.

By using the HVAC Remote Diagnostics solution, the VRF expert gained remote access to the site’s data. Based on the data, he suspected a swap of control lines between the two units (in this case: AV and Bedroom 1).

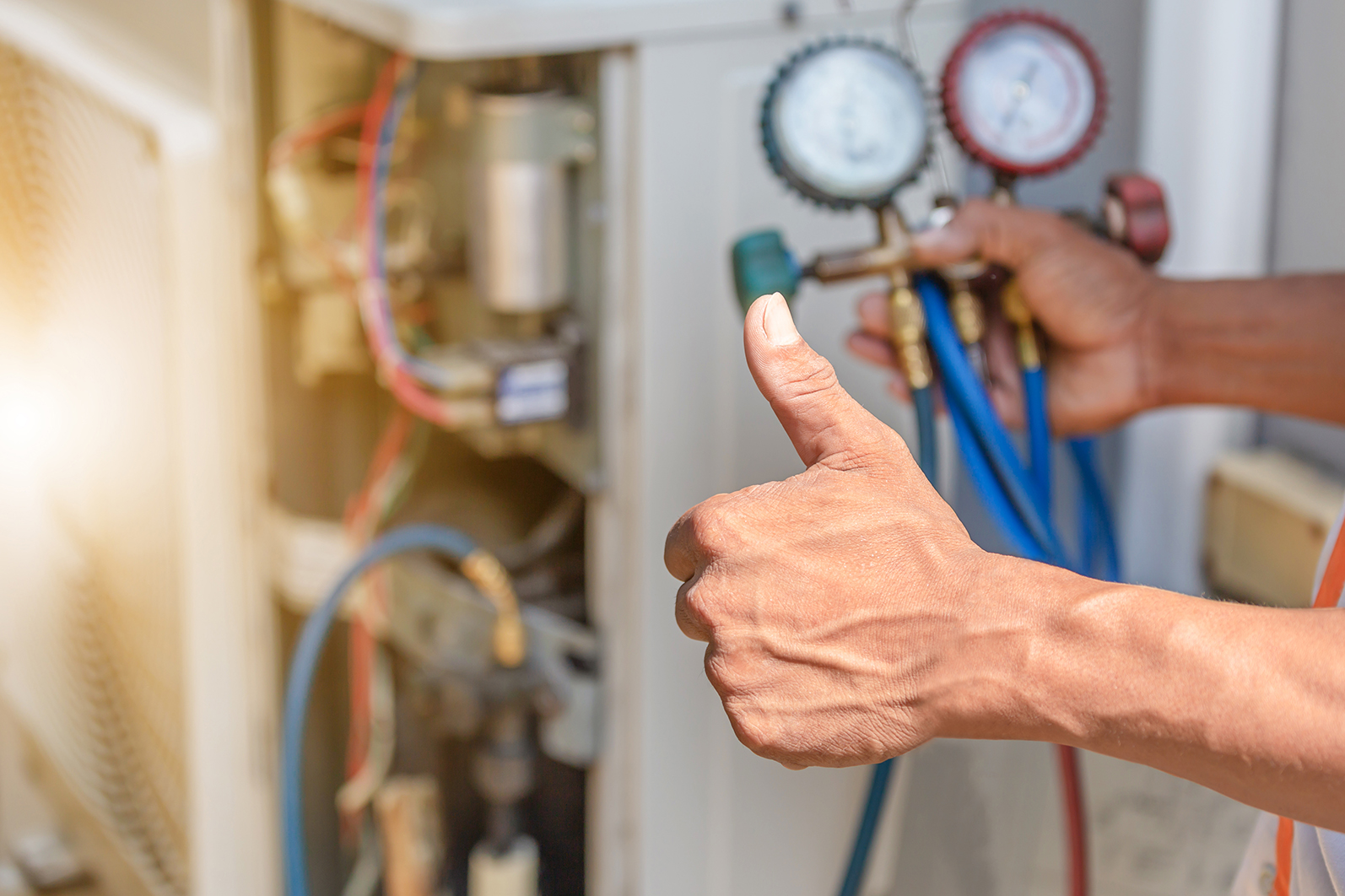

A team of junior service providers was sent to the site. Upon arrival at the site they opened the ceiling, and indeed – the control lines were swapped between the units.

After fixing the issue technically, the team used the HVAC Remote Diagnostics solution again. They repeated the operational sequence and saw that now, both units were working correctly.

And so, the root cause was reaffirmed: the control swap was probably the major factor in the compressor(s)’ fault, and liquid refrigerant may have entered the suction pipe.

| Traditional HVAC Service | Remote HVAC Service |

|---|---|

On-site long data recording with the essential need for the error to re-emerge (will not appear if both units are operating) | Offsite remote system test and fault finding |

Multiple trips to the site are expected | Less than 1 hour of on-site junior VRF service provider |

Analysis of the raw data gathered with minimal assistance from the tool, involving a Senior VRF expert on-site for a considerable amount of time | Remote fix verification |

On-site fix | |

On-site verification test |